Hosokawa Alpine American

455 Whitney Street

Northborough, MA 01532 US

508-655-1123

halpine.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Hosokawa Alpine American Supplies the Following Products

- Air Rings and Internal Bubble Cooling Units

- Closed-loop Process Control Systems

- Coextrusion Dies, Feedblocks

- Extrusion Dies

- Film Take-off Systems

- Film, Sheet, Coated Web Thickness Measuring Equipment

- Orientation and Tentering Equipment (for Webs)

- Single-screw Extruders

- Web Winders, Unwinds, Rewinds

Editorial, News, and Products

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

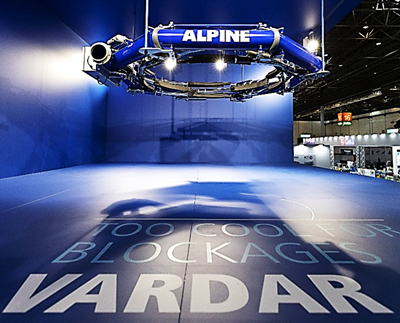

Novel Cooling System, Energy Efficient Extruders for Blown Film

NPE2024: Tower-mounted, variable-diameter air ring and flexible, energy-efficient extruder highlight Apline display.

-

ADG Solutions Expands Recycling Product Line

ADG will offer recycling equipment from Baracco and Break Machinery.

-

Flexible, Multilayer Film Made With 50% Reclaim

Target for new film is mono-material packaging to replace difficult-to-recycle multi-material structures in applications that include stand-up pouches.

-

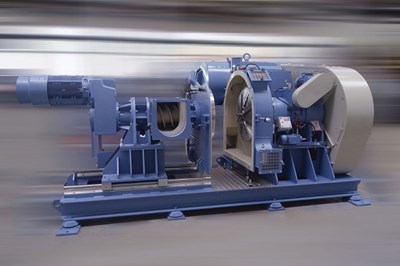

Single-Inlet Air Ring

Easy to maintain an operate, it’s integrated in the blown film line through just one cooling air supply line.

-

Recycling Challenges Become Opportunities with the Aid of New Technologies

The latest recycling equipment on view at the K Show handles more materials, is more efficient and produces higher quality output than ever achieved before.

-

Variable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

-

Alpine American PTXPO Spotlight

Hosokawa Alpine American, Inc. discusses the upcoming Plastics Technology Expo (PTXPO) March 29-31

-

'Circular Economy' Dominates Discussion of Resins, Additives at K 2019

New product launches from materials suppliers at the giant show shine light on sustainability.

-

Film Extrusion: Towers of Power & Sustainability

At K 2019, developments in blown film highlighted recyclable film structures for new applications and technology aimed at making product changes more efficient.

-

NPE2018 New Technology Focus: Film & Extrusion Coating

Check out what’s new in blown and cast film and extrusion coating at the big plastics industry trade show.

-

Are Blown Film Processors Getting The Biggest Bang for Their Resin Buck?

Decades-old extrusion equipment may be holding some processors back, says Alpine exec Nunes.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

K 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

-

Alpine Piled on the Layers At K 2016

A record for film blowing at a show: 11 layers.

-

Alpine Kicks Off K With Lots of Layers

Layers are great with chocolate cake. And blown film too. Hosokawa Alpine ran what’s believed to be a show first: an 11-layer line producing nylon-based barrier film.

-

K 2016 Preview: Extrusion and Compounding

Regardless of what you might be extruding, the themes of speed and flexibility will loom large in extrusion at the giant show.

-

Nova Installs Nine-Layer Blown Film Line to Enhance Customer Collaboration

It's said to be a first for PE resin producers in North America.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

K 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

-

Packaging Powerhouse Does It All

Materials formulation, cast and blown film extrusion, sheet extrusion, printing, and laminating come under one roof at this processor.

-

Modified MDO Gives Higher Film Yields

Hosokawa Alpine American, Natick, Mass., is offering new machine-direction orientation (MDO) technology that is said to dramatically reduce the amount of film to be edge-trimmed compared with other MDO designs.

-

Extrusion & Compounding at NPE: Advances Push Efficiency Envelope

Blown film towers may have been scarce, but there was no shortage of new technology aimed at helping to make extrusion processors more profitable.

-

Extrusion & Compounding at NPE: More Output, More Flexibility, Less Energy

There won't be many blown-film lines running, but there is still much in the way of innovation going on in extrusion and compounding.

-

From the Ashes, A More Efficient Film Operation Emerges

Three years after a fire destroyed most of its operation, Tex-Trude came back as a more productive extrusion business.

-

Processor Strategies - Cadillac Products Packaging Move to Nine Layers Means Better Bags, High-Value Niches

The story of Cadillac Products Packaging is a 65-year-old tale that combines a steadfast commitment to innovation and customer satisfaction with a broad range of product offerings.

-

EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

-

K 2010 Preview, Extrusion More…Layers, Output & Quality

In most segments of extrusion technology, the word at K 2010 is more.

-

Seven-Layer R&D Line Spurs Blown Film Innovation

Business might be slow in most blown film extrusion markets, but leading-edge processors are preparing for better times by tapping into a seven-layer line installed last year at Dow Chemical Co.’s Film Application Development Center (FADC) in Freeport, Tex.

-

NPE News in Extrusion

This NPE show won’t have a lot of extruders on the floor, either running or static. Instead, look for videos and announcements of new technology. You will also find lots of ingenious peripheral devices to improve output and quality and save resin. Some will do all three, and cost less into the bargain.

-

Investing in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

-

K 2007 Extrusion: Extrusion Outputs Go Through the Roof

Dramatic production demonstrations of cast and blown film set throughput records on the show floor in Dusseldorf.

-

What's New at the Show in EXTRUSION

It’s all about higher speeds and higher outputs at this year’s “K” show in Germany.

-

More Filler, Less Resin: Bag Films Load Up to Cut Costs

Filler isn’t a bad word in T-shirt bags and can liners any more.

-

NPE 2006 News Wrap-Up: Extrusion

NPE 2006 presented a bevy of features to make film, sheet, pipe, and profile extrusion more efficient.

-

MDO Films: Lots of Promise, Big Challenges

Machine-direction orientation is still discovering new market opportunities. But the technical difficulties are so great that some big projects never came of age. New equipment could make it easier.

-

K 2004 Extrusion: Outputs Rise, Downstream Units Gain Flexibility

The show was packed with new equipment for pipe and profile, including extruders redesigned for higher outputs and/or lower cost, plus new ways to adjust die and calibrator diameters or switch dies and calibrators more quickly.

-

K 2004 News Preview: Extrusion

At K 2004, at least a half-dozen European machine builders will show new direct-drive extruders running gearless—or nearly gearless—drives with substantially higher rpm and output rates than conventional extruders of the same size.

-

Winders: They're Pushing New Limits In Speed and Tension Control

New-generation winders for blown and cast film are winding bigger, better rolls at higher speeds and lower tension. They've gotten so fast that cast film lines can now realize their full productive potential.

-

NPE News Wrap-Up: Extrusion

Gearless extrusion, cryogenic profile calibration, wireless data communications, and automatic start-up of blown film lines are just a few of the new ways to raise efficiency and output that were highlighted at NPE.

-

Extrusion (K 2001 Preview)

Probably the most intriguing news in extrusion at K 2001 will be a novel way to extrude clear film that differs from standard blown and cast methods.