PET Processing - Extrusion

Latest PET Processing - Extrusion Articles

VIEW ALLDeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

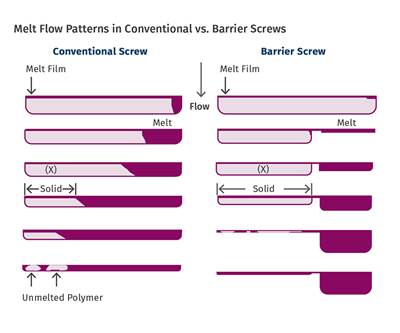

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreInnovation, Customization & Sustainability: How Flex Films Focuses on U.S. Market

Global player in BOPET film has big plans for U.S. market with innovative products developed collaboratively with customers while paying heed to environmental concerns.

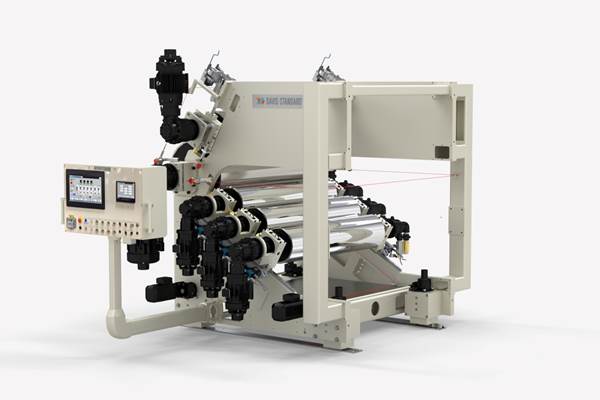

Read MoreKanarski to Lead Davis-Standard’s Technical Product Team

Will collaborate with suppliers and customers to evaluate market trends and capabilities, and develop technology accordingly.

Read MoreDavis-Standard Adds James Johnson as Regional Sales Manager

‘Brings industry sales, manufacturing and adhesives experience to position.’

Read MoreNDC Names Perry V.P. Sales/Marketing

Gauging specialist hires sales veteran to lead global team.

Read MoreLatest PET Processing - Extrusion News And Updates

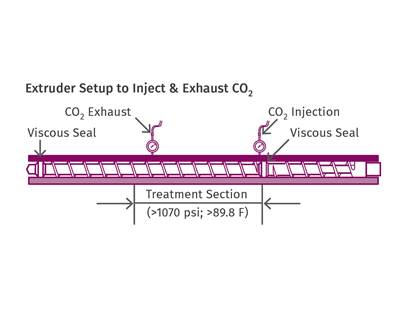

South Korean Machine Builder Licenses Novel Foam Processing Technology

New technology takes aim at foaming semi-crystalline polymers such as PLA, PET and PP.

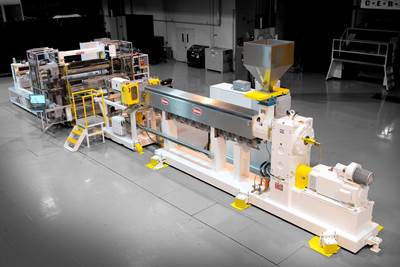

Read MoreExtrusion: Two-Stage Screw Offers Distributive, Dissipative Mixing

New design from Davis-Standard offers outputs comparable to barrier screws at lower melt temperatures.

Read MoreExtrusion: 'Unique' Digital Services for Film Processors

Four-module platform aims at transparent, faster and more efficient service for biax-film processors.

Read MorePTi Realigns Sales Team

Additions made as machine builder continues its emphasis on high-quality sheet extrusion its importance to the thermoforming process.

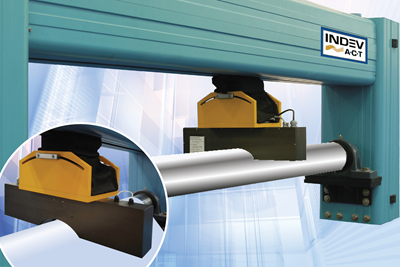

Read MoreExtrusion: Non-Contact, Single-Sided Film, Sheet Gauge

Applications include a wide range of non-metallic film and sheet up to 200 mils.

Read MoreFilm/Sheet: Web Gauging Products for Sheet, Film

New series of new web-gauging product to boost film and sheet quality.

Read MoreFeatured Posts

What You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

Read MoreTry This Approach to Clean Up Your Recycled Material

CO2 can be used as a totally “green” solvent to remove many kinds of contamination in recycled plastics without the need for toxic solvents.

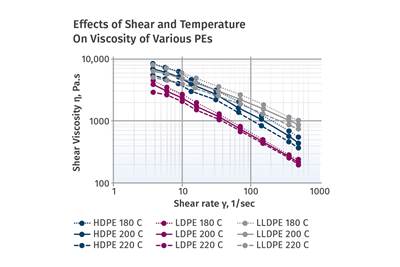

Read MoreUnderstanding Viscosity in Extrusion

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

Read MoreK 2019 Preview: Green's the Theme in Extrusion & Compounding

Themes of sustainability and the Circular Economy will be visible at the booths of many suppliers of extrusion and compounding equipment—film, in particular.

Read MoreGiving the ‘Royal’ Treatment in PET Packaging

In the U.S. for just seven years, Royal Interpack is emerging as a growing, innovative, customer-centric supplier of food packaging.

Read MoreUnder One Roof: Innovative Recycler Closes the Loop

rPlanet Earth looks to disrupt the plastics recycling industry by creating a truly sustainable, closed-loop system for recycling and reuse of post-consumer plastics, with reclaim, sheet extrusion, thermoforming and preform making all in the same plant.

Read More