Articles

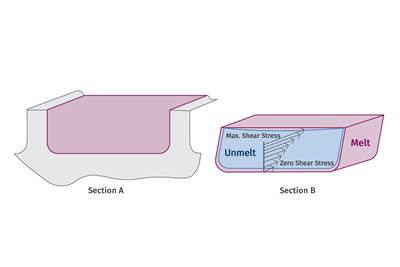

The Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreDr. Walter Kaminsky: Pioneer of Catalysts Revolutionizing Polymer Production and Recycling

Dr. Walter Kaminsky’s pioneering research on metallocene catalysts at the University of Hamburg sparked a global revolution in plastics production. Inducted into the Plastics Hall of Fame in 2024, Kaminsky’s legacy continues to shape the polyolefin industry and plastic recycling technologies.

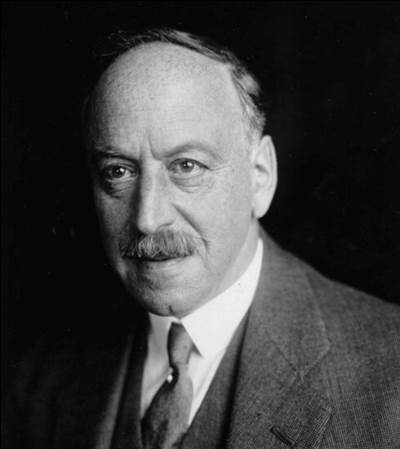

Read MoreArthur Eichengrün: Pioneer of Cellulose Acetate Manufacturing Processes

Explore the legacy of Arthur Eichengrün, a trailblazer in 20th-century chemistry and materials science, whose achievements reshaped both medicine and the plastics industry. His groundbreaking contributions led to his induction into the prestigious Plastics Hall of Fame in 2024.

Read MoreGeorge Victor Sammet Sr.: Pioneer of the Plastics Industry

The remarkable journey of George Victor Sammet Sr., a leader in the early days of the plastics industry, includes groundbreaking inventions and the establishment of key industry organizations such as the Society of the Plastics Industry (SPI).

Read MoreConsistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreA Lifetime of Innovation in Plastics Machinery: Wolfgang Meyer

Wolfgang Meyer, a German mechanical engineer and industry leader whose contributions to plastics machinery have shaped the industry. Inducted into the Plastics Hall of Fame in 2024, Meyer’s work in injection molding, blow molding and sustainability has left an enduring legacy.

Read MoreInnovator and Architect of INSITE Technology: Kurt Swogger

The pioneering legacy of Kurt Swogger at Dow Chemical Co. revolutionized the plastics industry with INSITE Technology. Inducted into the Plastics Hall of Fame in 2024, Swogger’s innovations in high-performance polyolefins have shaped industries worldwide.

Read MoreChihiro Kanagawa: PVC Pioneer and Environmental Steward

Follow the legacy of Chihiro Kanagawa, a pioneer in the PVC industry and advocate for sustainable growth. Chairman of Shintech, his vision transformed PVC manufacturing.

Read MoreThe Titanium Man: Arthur P. Haag's Legacy in Plastics Innovation

Learn about Arthur P. Haag, the visionary behind purity titanium catalysts, whose innovations revolutionized plastics manufacturing for decades. He was inducted into the Plastics Hall of Fame in 2024.

Read MoreDr. Cato Laurencin: Pioneer in Plastics for Regenerative Medicine

Dr. Cato Laurencin, whose groundbreaking work in plastics and regenerative medicine has transformed health care, was inducted into the Plastics Hall of Fame in 2024. Dr. Laurencin's innovative use of polymers for musculoskeletal applications has revolutionized medical devices and biologics.

Read MoreShaping Talent in Plastics: The Legacy of Professor Nick R. Schott

Delve into the career of Dr. Nick R. Schott, a figure in plastics technology, whose pursuit of excellence and commitment to innovation have left a legacy.

Read More