Articles

Innovator in Polymer Science and Education: Dr. Joseph A. Biesenberger

Dr. Joseph A. Biesenberger, a pioneer in polymer science and education, was inducted into the Plastics Hall of Fame in 2024. From founding the Polymer Processing Institute to seminal works in reactive polymer processing, his impact continues to shape the plastics industry.

Read MoreH. Joseph Gerber: Pioneer of Plastics Innovation for Various Industries

The remarkable legacy of H. Joseph Gerber in plastics revolutionized multiple industries. Inducted into the Plastics Hall of Fame in 2024, Gerber's inventions — including computer-controlled fabric cutting and CAD/CAM systems — continue to shape manufacturing processes worldwide.

Read MoreJacques Edwin Brandenberger: From Patented Viscose to Cellophane Innovation

Get to know the story of Swiss chemist and textile engineer Jacques Edwin Brandenberger, whose invention of cellophane in 1908 revolutionized the packaging industry. He was inducted into the Plastics Hall of Fame in 2024.

Read MoreLuigi Bandera: Pioneer of Plastic Extrusion With Vision

Get to know the life and legacy of Luigi Bandera, the visionary behind Costruzioni Meccaniche Luigi Bandera, who revolutionized plastic extrusion technology and earned a place in the Plastics Hall of Fame in 2024.

Read MorePLASTICS Names McGwire Winner of 2024 William R. Carteaux Leadership Award

Member of PLASTICS for more than 40 years served on several committees and boards since 2005, including a stint as chairman.

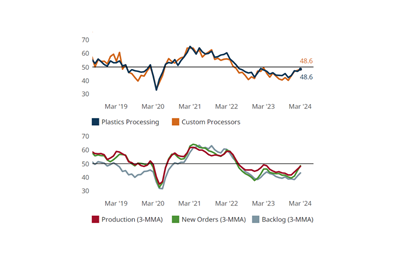

Read MoreProcessing Making Slow, Steady Progress

Plastics processing activity didn’t make its way into expansion territory in March, but seems headed in that direction.

Read MoreIn the Zone: Packaging Part 2

Check out the Packaging Zone at NPE2024 and explore the latest in both flexible and rigid packaging.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreBASF Chair to Keynote on Firm's Sustainability Path

Chair, CEO Heinz to discuss materials giant's sustainability journey.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE 2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read MoreScrew Design Tips to Boost Productivity

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankland and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

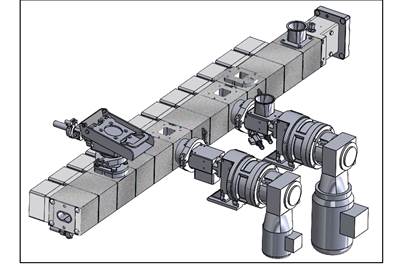

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read More