SIGMASOFT Virtual Molding

10 N Martingale Rd.

Ste. 620

Schaumburg, IL 60173 US

847-558-5600 | 847-558-5600

sigmasoftvm.com

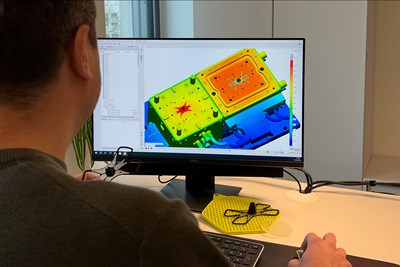

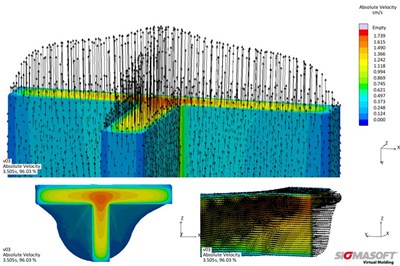

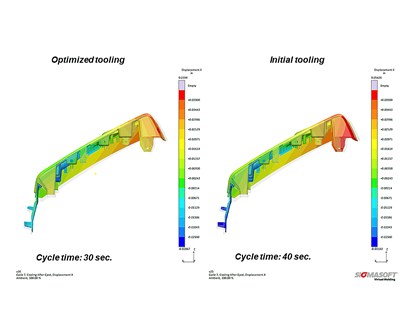

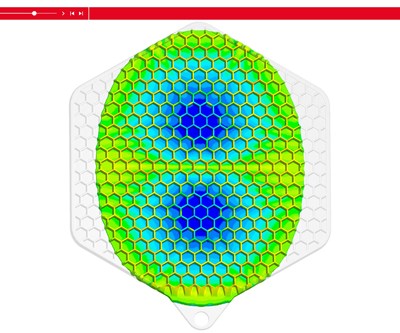

About SIGMASOFT Virtual Molding

We use technology to prevent and solve molding problems. We help companies frustrated by issues on the production floor, concerned about the time and cost of trial-an-error, and worried about quality issues that negatively impact the bottom line...

Does any of that resonate with you?

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

SIGMASOFT Virtual Molding Supplies the Following Products

Trade Names Offered by SIGMASOFT Virtual Molding

- SIGMASOFT®