DME Company

29111 Stephenson Hwy.

Madison Heights, MI 48071 US

800-626-6653 | 248-398-6000

dme.net

About DME Company

DME is committed to earning your business everyday by brining you new, innovative and cost-effective products and services. Time earned knowledge, molding industry expertise and cutting-edge technology makes us the company to partner with for your next project. Our goal is your success.

IS THIS YOUR COMPANY?

Video Gallery

EcoONE Hot Runner Systems Final V1 2024 03 11

StellarONE Hot Runner Systems Final V1 2024 04 04

IM&D DME Mold Base 2

Learn about the DME 2.0 Mold Bases. These have interchangeable plate systems. Available in #1 and #7 Steel. Some cool ...

Visit DME.net Today! Remarketing Video.

Come back to DME and make a purchase today. Visit us to get started. Many people love our ejector pins, gate cutters, mold ...

As Seen On Plastics Technology

DME Company Supplies the Following Products

- Air Knife Equipment

- Automation/Systems Integration

- Blenders (non-intensive)

- Box Tilters

- Clamps, Holding Devices

- Clean Rooms and Components

- Closed-loop Process Control Systems

- Compression/Transfer Molds

- Conveyors (parts-handling)

- Cooling Towers

- Core Materials

- Cutting Tools

- Degating Equipment

- Desiccant for Dryers

- Dryers for Resins

- Dust Removal Equipment

- Fasteners

- Flow Monitoring/Control Devices (for Liquids)

- General Purpose Robots and EOAT

- Granulators

- Heat Exchangers

- Heat Pipes and Related Thermal Conductors

- Heat-recovery Systems

- Heat-transfer Fluids

- Heaters, Heating Elements

- Hopper Loaders

- Hoppers, Bins, Tanks

- Hot Runner Components

- Hydraulic Components and Systems

- Injection Molding Machines

- Injection Molding Non-return Valves

- Injection Molding Nozzles

- Injection Molds

- Inserts

- Knives for Granulators, Pelletizers

- Lifting Devices

- Liquid Resin Filtration Materials, Equipment

- Lubricants

- Machining, Drilling, Routing Equipment

- Metal Detectors, Separators

- Mold Components

- Mold Making and Repair Equipment

- Mold Steels

- Mold-cleaning and Maintenance Chemicals

- Mold/Tooling Design Services

- Motionless Mixers

- Part or Sprue Removal Robots and EOAT

- Particle Screeners, Classifiers, Separators

- Pelletizers

- Pneumatic Components (including Compressors)

- Pressure Controllers, Monitors

- Pressure Sensors, Transducers

- Prototype Molds

- Purging Compounds

- Quick-mold-change Equipment

- Rebuilt Screws or Barrels

- Recording Instruments

- Release Agents--External (Spray or Wipe-on)

- Screw Tips

- Static-eliminating Equipment

- Steels

- Temperature Controllers, Monitors

- Temperature Pyrometers, Sensors, Thermocouples

- Thermoforming Molds

- Timers

- Ultrasonic Welding

- Valves, Gates, Diverters

- Water Treatment/Filtration Systems

- Water, Oil Manifolds and Couplings

Editorial, News, and Products

-

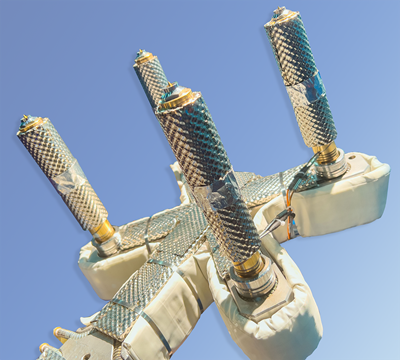

Compact Collapsible Core Features Independent Movements

NPE2024: DME’s DURA collapsible core’s two-piece design enables each segment to open and close independently.

-

NPE2024 Features Medical Industry Sessions

Learn about trends in sustainability, materials, collaboration and more at the NPE2024 Medical Industry Sessions.

-

Fakuma 2023: Configurable Control Units and Linear Actuators for Injection Molds

Servomold will introduce a new generation of control units for servo drives and a new series of actuators for the execution of linear movements in injection molds.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

DME to Unveil New Units, Products at K 2022

DME will highlight new products from three newly organized business groups: DME Thermal Management Solutions, DME Modular Mold Systems and DME Digital IoT Controls.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

Injection Molding Live Demos to Highlight First-Ever PTXPO

Major suppliers will be running injection machines in the first plastics industry trade show in the Chicago area since 2009.

-

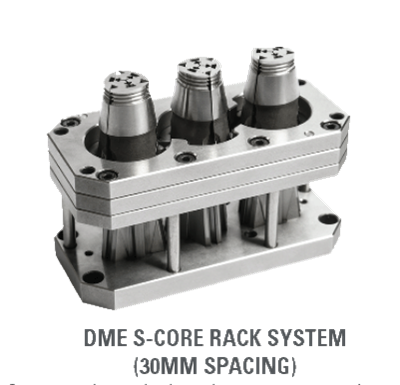

Collapsible Core Promises Long Service Life, Flexibility

DME's S-Collapsible cores can be configured as small as 6 mm or as large as 400 mm.

-

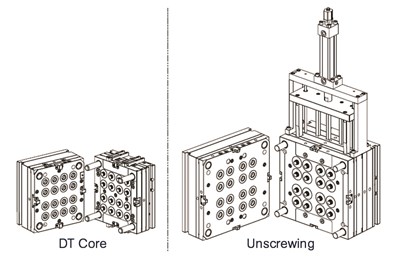

Servo Unscrewing Device

Designed to replace hydraulic cylinders, DME's Servomold internal treaded cores are available in multiple configurations

-

Novel External Latch Lock Design

DME says its patent-pending EZ-Latch Lock provides a long-lasting, reliable and easy-to-install lock for plate sequencing.

-

Redesigned Roller Lock Available in Three Advanced Materials

DME new LT-Series LifeTime Side Locks come in D2, DC53, or 440C stainless steel, depending on the tool’s requirements.

-

Self-Adjusting Precision Lifter

DME’s Accualign lifter features a multi-axis self-adjustment system that compensates for misalignment.

-

'Circular Economy' Dominates Discussion of Resins, Additives at K 2019

New product launches from materials suppliers at the giant show shine light on sustainability.

-

K 2019 Report: More Control, Faster Ordering for Molds, Hot Runners

Online monitoring of existing systems and configuration and ordering of new molds were featured at K 2019, as were numerous advances in valve-gate controls.

-

Data Driven, Employee Owned

Approaching its seventh decade in business, PTA Plastics has shifted its location and remade its customer base since its founding in 1953, but many things have not changed in the intervening years, including an emphasis on people and leading-edge technologies.

-

K 2019 Preview: Molds and More at the Messe

Here’s news to look for in molds, mold components, hot runners and controls at the giant K fair in October.

-

Hillenbrand Inc. to Acquire Milacron Holdings

Milacron joins Coperion, Rotex, and other industrial holdings under the Hillenbrand umbrella.

-

Tooling: Off-the-Shelf Conformal Cooling via Standardized Components

Ready-to-order conformally cooled cold-sprue and hot-drop bushings from Milacron’s DME business allow molders to reap the benefits of 3D printed cooling channels in key areas of the tool without the cost of one-off custom analysis, design and fabrication.

-

Better Options for Mold Cooling—The ‘Next Frontier’ in Process Control

New concepts in mold temperature-control units, conformal cooling, and more in Tooling & Cooling session at Molding 2019 Conference.

-

NPE2018 New Technology Focus: Mold Components, Supplies, Maintenance

Advances include new approaches to tool maintenance and monitoring.

-

Hot Runners & Tooling at NPE2018: Smarter & More Specialized

Hot-runner technology, like the companies utilizing it, is becoming highly specialized, building in focused functionality for the application to be molded. Like most of the equipment in the cell around it, it’s also becoming smarter, sharing data and reacting to feedback from the press and more.

-

At NPE: 3D Printed Molds

UV photopolymer produces short-run cavity inserts.

-

News in Hot Runners & Tooling At Fakuma 2014

Novelties included variable-pitch manifolds, mold servo controls, 3D printed plastic mold inserts, and flexible/formable cooling channels.

-

Mexico’s Auto Market Accelerates, Brings Plastics Along

Mexico’s booming automotive industry inevitably became part of the conversation with exhibitors at the country’s largest plastics trade fair, Plastimagen.

-

Your Options for Mold Venting

When should you use machined vents or porous, sintered metals? Here are some guidelines.

-

Relief for Hot Summer Toolrooms

DME thinks of your mold techs in the dog days of summer.

-

Two New Blow Molding Tech Centers

Uniloy offers a range of new and expanded services for extrusion blow and injection-blow molders.

-

DME Moves Closer to Molders & Moldmakers in Mexico

DME sets up permanent office to support Mexico's fast-growing plastics industry.

-

News in Hot Runners & Tooling at K 2013

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show.

-

Seven Tips to Maximize Hot-Runner Performance

A complex variety of factors affects the success of processing with a hot-runner system. Nevertheless, you can reduce this complexity and handle many of the issues by addressing a few key issues.

-

TOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

-

Tooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

-

TOOLING: Standard Components and In-Mold Monitor at K 2010

K 2010 news in tooling aims at helping injection moldmakers speed product to market.

-

Hot Runners for Large & Small Parts Debut at NPE 2009

Although we previewed a number of new developments in hot-runners at NPE 2009 in our May and June issues, the big show in Chicago served up still more new offerings for PET preforms, medical parts, caps and closures, and more.

-

NPE News in Injection Molding

If a better machine can help your company beat challenging economic conditions, you’ll probably find it at NPE. And finding it will be easier, thanks to our editors’ efforts to sift out of some 2000 exhibits the most significant news in injection and blow molding, extrusion, compounding, and thermoforming.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

Unbalanced? No Shortage of Ways to Fix Uneven Filling of Multi-Cavity Molds

The accepted ground rule for balancing melt flow in multi-cavity injection molds is to achieve equal flow distance from the injection point to each cavity.

-

Novel Ejector System Eliminates Plates and Pins

Injection mold cost savings, greater molding productivity, and better part quality are promised for a new ejection system that does away with conventional ejector plates, housings, pins, and risers. This approach is said to reduce mold height, shorten mold-open times by at least 10%, enable better optimization of mold cooling—not to mention eliminating ejector marks on parts.

-

CAD Evolution For 3D Mold Design

Specially tailored packages of 3D computer-aided design software have been available to injection mold designers for at least a decade.

-

Injection Molding LSR: Three 'M's of Innovation: Mega, Micro, and Multi

Liquid silicone rubber is breaking out of its niche into a broader array of applications, helped by new developments in materials, machinery, and processing. Larger parts, micro-parts, foams, and multi-color or multi-material combinations are key areas of innovation.

-

Hot-Runner News at K 2007

While a number of exhibitors at the “K” show in Dusseldorf are keeping their new entries under wraps until showtime later this month, some suppliers have released a few details on their new hot-runner components and controls.D-M-E will introduce the Bacchus hot-runner system for crates and packaging.

-

NPE 2006 News Wrap-Up: Hot Shots: New Nozzles and Controls Add Sizzle to Runnerless Molding

Electrically driven valve pins, a low-cost alternative to valve-gating, mold-mounted temperature controllers, and new components for fast color changes are some of a host of new components and systems unveiled at the giant NPE 2006 show in Chicago this past June. (Some brand-new introductions since the show are also included in this report.) The news includes runnerless products aimed at everything from micromolding to shot weights up to 17.4 lb.

-

NPE 2006 News Wrap-Up: Testing and QC--New Lab Instruments Stress Affordability and Convenience

Thermal and mechanical testers, color and appearance sensors, vision inspection devices and CMMs—the NPE had them all in more compact, economical, and easy-to-use models.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

Rapid Tooling: It's Faster in Molding, Too

Rapid tooling technology is not just about speedy moldmaking. Now it also signifies higher productivity in molding. The latest RT technology achieves dramatically faster cooling and stands up to long-run molding, as well.

-

Mold Designers Put the Web to Work

The internet is redefining the tool-design process. Some mold designers are finding that using the Web to manage a tool project can shorten lead times, cut costs, and make sure vital data get to all participants in a project.

-

Sequential Valve Gating

Ultimate Control for the Toughest Molding Jobs

-

NPE 2003 News Wrap-Up: Hot-Runner Temperature Controls

Sophisticated hot-runner temperature controls introduced at the NPE show in Chicago store set-up data right on the mold, detect (and even fix) thermocouple wiring mistakes, and employ easier-to-use icon-based displays.